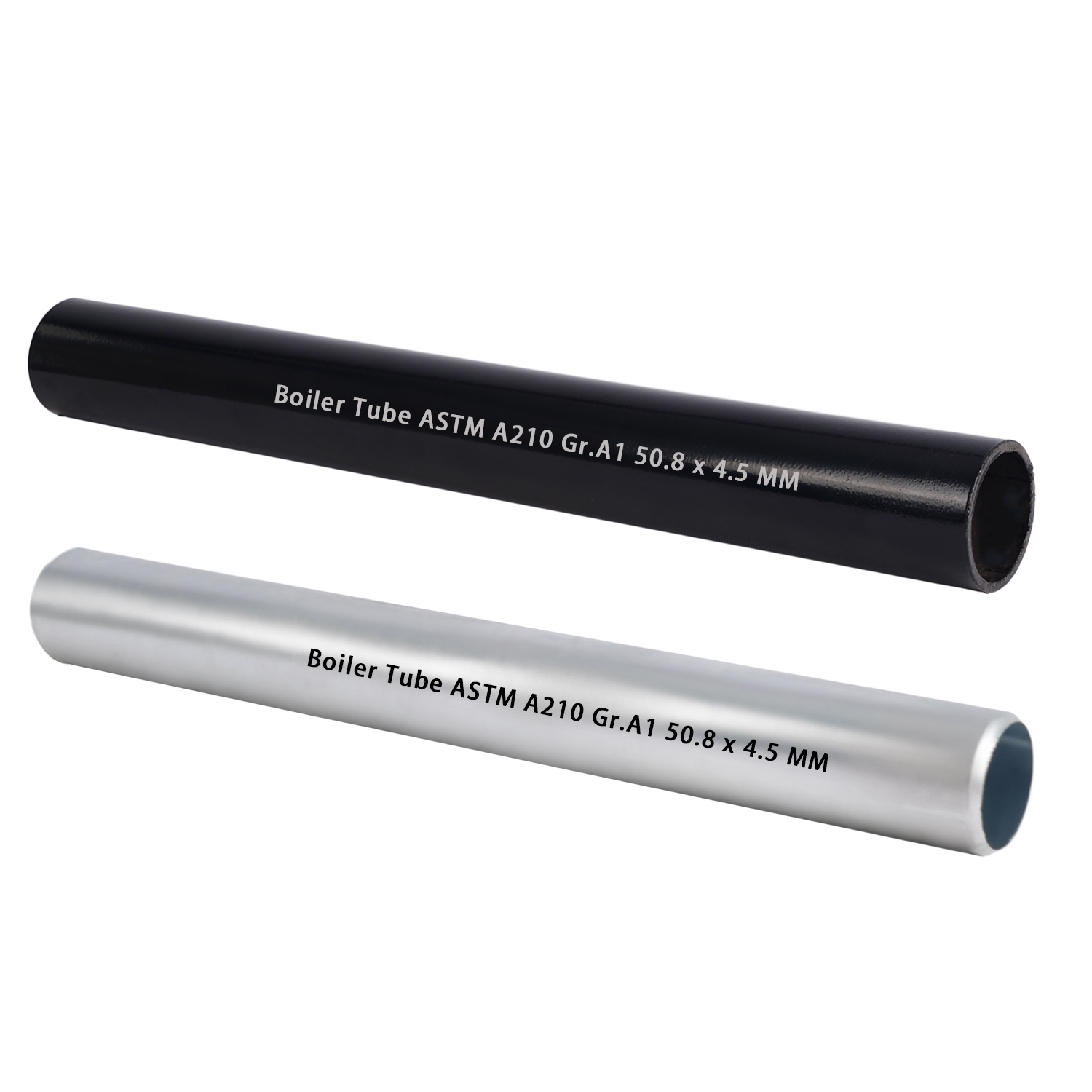

ASTM A210 Alloy Boiler Tubes

ASTM A210 / A210M, ASME SA210 / SA210M Grade A-1 is the standard applicable to Seamless Medium-Carbon Steel Boiler and Superheater Tubes.

Application

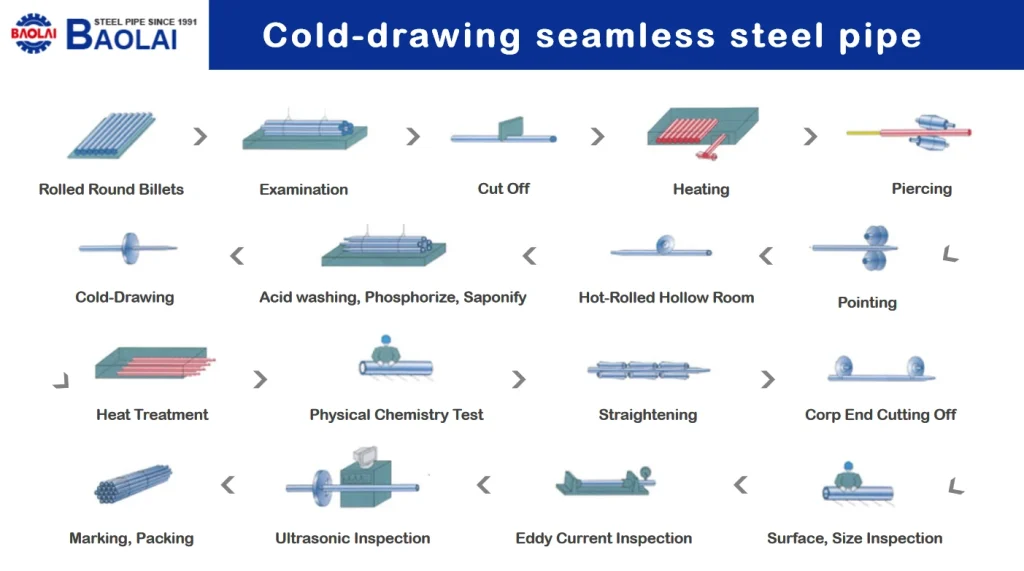

Production Process Introduction

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products. Produced from hot rolled 1026, the cold drawing process increases the tube’s physical properties and offers better tolerances and reduced machining allowances over hot finish seamless.

CDS seamless tube and pipe is produced by piercing hot billets and subsequent rolling which reduces their diameter and elongates them. This material is then passed through a die and over a mandrel plug to produce an accurate size and gauge which is the essence of the cold drawing process.

Example Size

Note: Some of the main specifications are shown below, please contact us for more details.

Out Diameter | Wall Thickness | ||

Inch | mm | mm | |

1/4″ | 6.35 | 0.51/ 0.89/ 1.24/ 1.64 | |

1″ | 25.4 | 1.24/ 1.64/ 2.11/ 2.41/ 2.77/ 3.05/ 3.76/ 3.96 | |

2″ | 50.8 | 1.64/ 2.11/ 2.41/ 2.77/ 3.05/ 3.76/ 3.96/ 4.78/ 5.56/ 6.35/ 7.14/ 7.95/ 9.53 | |

3″ | 76.2 | 1.64/ 2.11/ 2.41/ 2.77/ 3.05/ 3.76/ 3.96/ 4.78/ 5.56/ 6.35/ 7.14/ 7.95/ 9.53 | |

4 3/4″ | 120.65 | 5.56/ 6.35/ 7.14/ 7.95/ 9.53 | |

One-stop service to facilitate your purchase

The Lai Group continues to provide service and support after your purchase. To save you time, we offer you numerous value-added services such as processing, logistics management and testing.

Processing Services:

- OEM & ODM

- Protective Coatings

- Saw and Flame Cutting

- Beveling, Threading and Grooving

For more information, please contact our service team.