Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

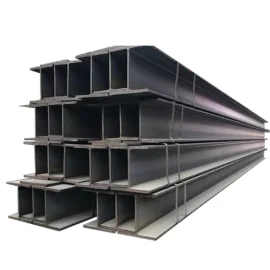

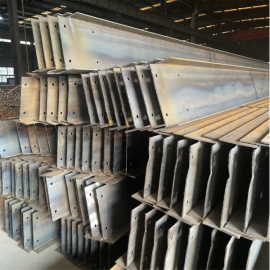

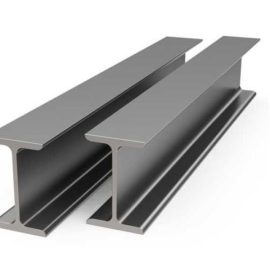

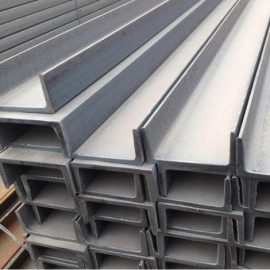

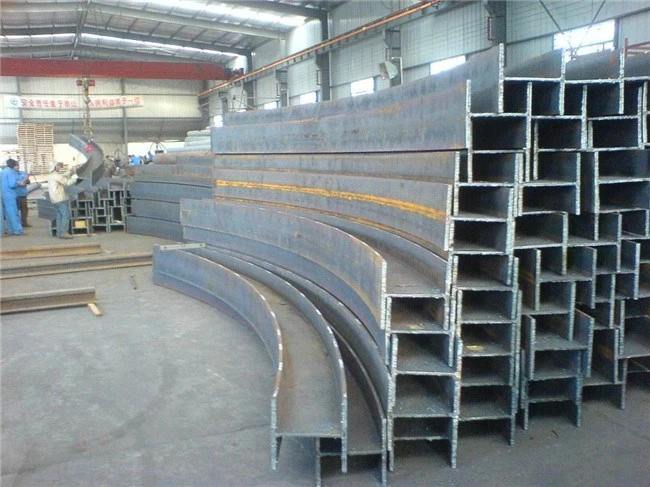

Section Steel

Depending on each project’s applicable specifications, the steel sections might have various shapes, sizes and gauges made by hot or cold rolling, others are made by welding together flat or bent plates. Common shapes include the I-beam, H-beam, Channels and so on.

Download DOC:📌PDF File