Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

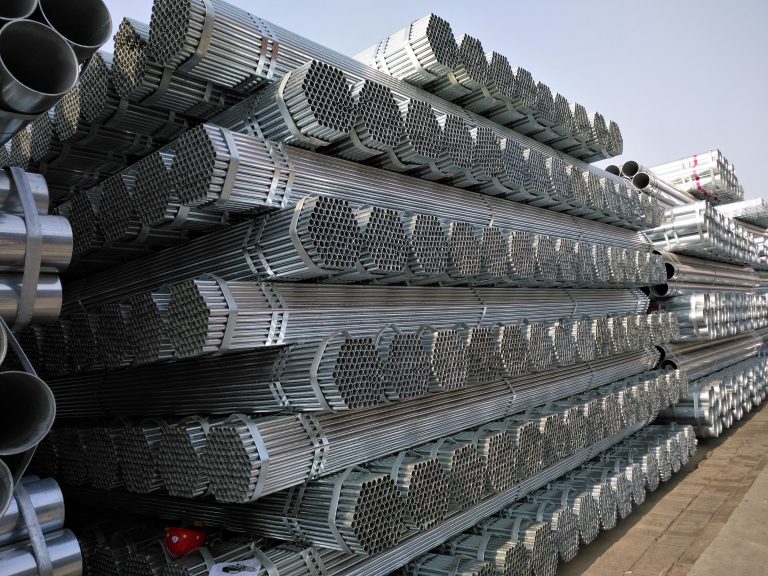

Galvanized Steel Pipe

Galvanization is a process that involves applying a protective coating of zinc to metals like steel or iron. The zinc coating offers protection against rust and corrosion, effectively increasing the durability or longevity of the metal. Lai provide Hot dipped galvanized steel pipe and pre-galvanized steel pipe to its customers.

Galvanized pipes are widely used. In addition to being used as pipeline pipes for general low-pressure fluids such as water, gas, and oil, they are also used as oil well pipes and oil pipelines in the petroleum industry, especially offshore oil fields, and oil heaters and condensation pipes for chemical coking equipment. Pipes for coolers, coal distillation washing oil exchangers, trestle piles, and support pipes for mine tunnels, etc.