Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

Application:Fire Sprinkler System

Project:Airport and Subway Fire Sprinkler System

Product:Fire Sprinkler Pipe, Grooved Fittings, Coupling, Flange, Flow Switch, Valves, etc

Specification:1/2”-10”

Quantity:500 Tons

Year:2020

Country:Colombia

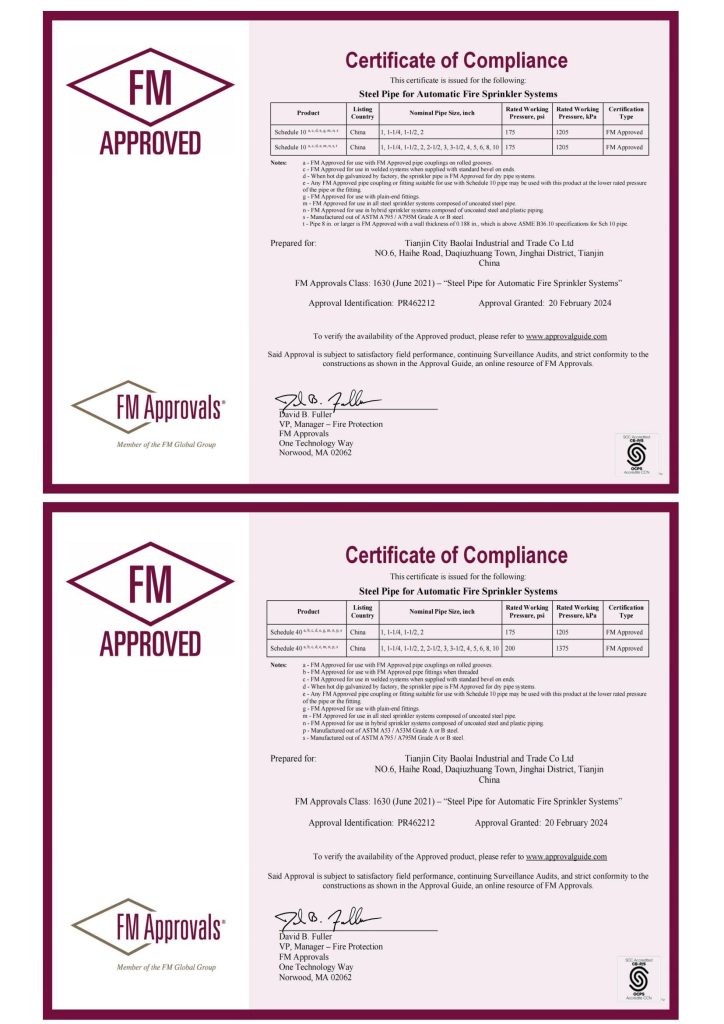

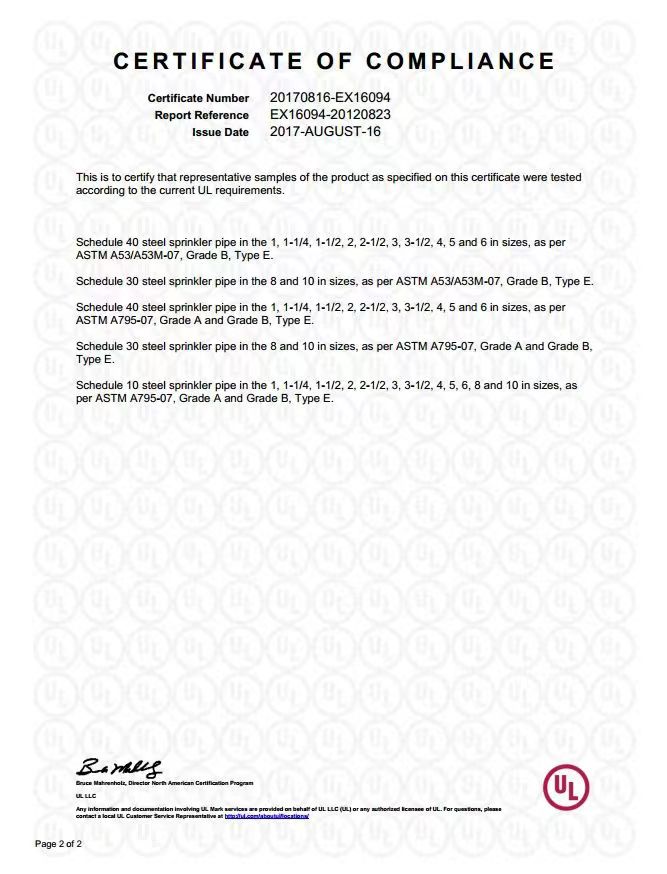

Certificate:UL & FM

Fire sprinkler pipes and fittings are normally composed of carbon steel or ductile iron and are used to transmit water or another liquid from one piece of firefighting equipment to another. It is also referred to as fire fighting pipe.

Fire sprinkler pipes usually use grooved connections, which are easier to handle than welding. Fire pipes must be painted red or covered with a red anti-corrosion epoxy coating in order to be distinguished from other pipeline systems, according to the applicable laws and standards.

Fire pipes demand a high level of quality control because they are often put in a static position. Lai Fortune provide high quality fire sprinkler pipes and fittings for all over the world buildings.

Produce according to the drawings and requirements provided by customers.

The seamless steel pipe or ERW steel pipe is produced and inspected, the steel pipe is grooved, sprayed with red paint or epoxy coating, packaged, and finally shipped to the customer.

For all of your fire safety and protection needs, trust the experts at Lai Group.

We will take care of your home or business! Just give us a call at 0086-022-83378888 / 0086-18315663796 or contact us online today!

Lai Gorup provides ERW fire sprinkler pipes with UL and FM 1630 certificates.

Also the fire pipe fittings and valves we can provide with UL and FM certificates.

Lai Group is a comprehensive enterprise with industry, trade and commerce,

which was established in 1991.

Our annual capacity is approximately 5 million tons and exports of 150,000 MT per year to South and North America, Europe, the Middle East, Africa, Australia and Southeast Asia.

We keep in touch with professional laboratories, which are equipped with advanced instruments and experienced researchers, to test the performance and improve the production process.

The groove system significantly reduces installation cost and time while providing a safer workplace as it does not require welding. This enables installation companies to do more work in less time. Grooved piping systems are easy to assemble and also make service and maintenance fairly easy.

We also provide plain ends, beveled ends, threaded ends, flange welded according to customer requested.

More than a manufacturer, we provide a one-stop solution for your business.