Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

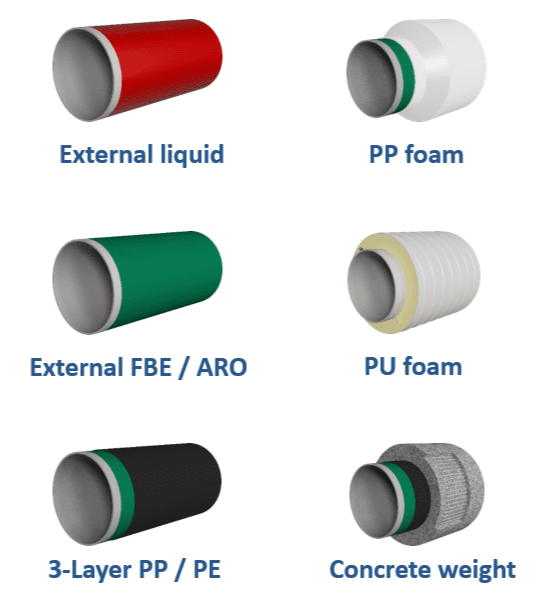

External Coating Pipe

Lai Steel offers external caoting services include FBE (fused epoxy), 2LPE, 3LPE, 2LPP, 3LPP, concrete weight and insulation coated pipe. They provide a barrier between the metal of the pipe and the environment, protecting the pipe from corrosion and other damage.

Coating services provided by Lai Steel have resulted in cost savings ranging from millions to billions of dollars in the construction of numerous oil, gas and water transmission projects.That’s why corrosion-resistant coatings for pipelines are critical to pipeline owners, who can’t afford transmission outages due to pipeline corrosion.