Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

Since 1995, Manufacturer has been helping our customers build a better world – making sustainable progress possible and driving positive change on every continent.

The company principally operates through three primary segments — Construction Industries, Resource Industries and Energy & Transportation — and provides financing and related services through its Financial Products segment.

PDF, 360KB

2023

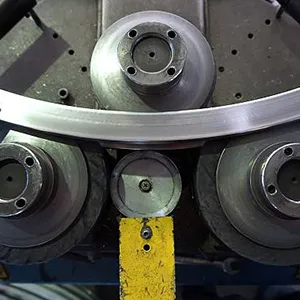

Our steel pipes are available with cut and roll grooves.

Roll Groove connection is the main connection method of fire protection pipes. It has the characteristics of convenient and fast installation, economical and environmental protection, the original characteristics of the pipes are not affected, and the maintenance is convenient.

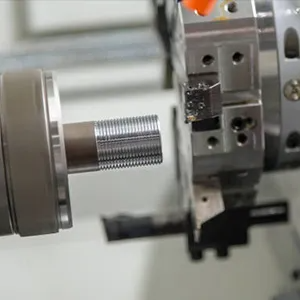

Pipe thread is a thread located on the pipe wall for connection, mainly used for the sealing connection of water, gas, oil and other pipelines. We offer NPT* and BSPT* pipe threads.

We can apply any type of Bevel to any degree desired. Beveling can be applied to the surface of pipes of any size or diameter.

Cut both ends of the steel pipe into planes at 90°to the axis, and there are no flying spurs.

Water cutting: Water jet technology, also known as water jet and water cutting technology, is a real cold cutting. It is a high-energy stream of water produced by pressurising ordinary water through a pressurised system, which is then jetted through very fine sand tube nozzles to cut at speeds approaching one kilometre per second.

We use hydraulic bending machine for bending, with high accuracy and good yield. It can be bent according to the bending angle provided by the customer.

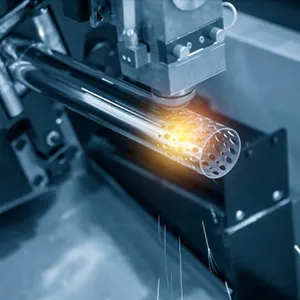

There are three ways to punch the steel pipe, one is the pipe body drilling, the second is the pipe body punching, and the third is the laser drilling. At present, laser drilling is widely used and has the characteristics of high efficiency and high precision.

We provide welding services for fittings to pipe or fittings to fittings.

More than a manufacturer, we provide a one-stop solution for your business.