Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

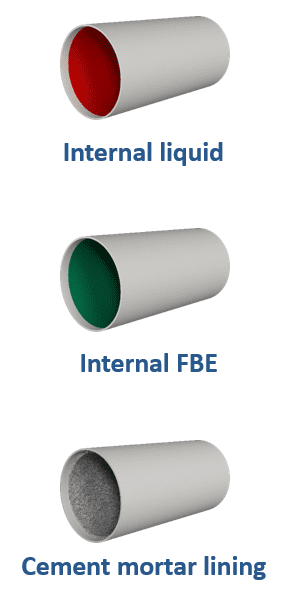

Internal Coating Pipe

Internal coating for pipelines is a process in which steel pipes are coated from the inside with a protective layer. This is done to resist fluid or gas flow in the pipe and to reduce friction and wear. Lai’s inner tube coating services provide flow efficiency and corrosion protection for gas, water, conduction and production pipelines.

No products were found matching your selection.