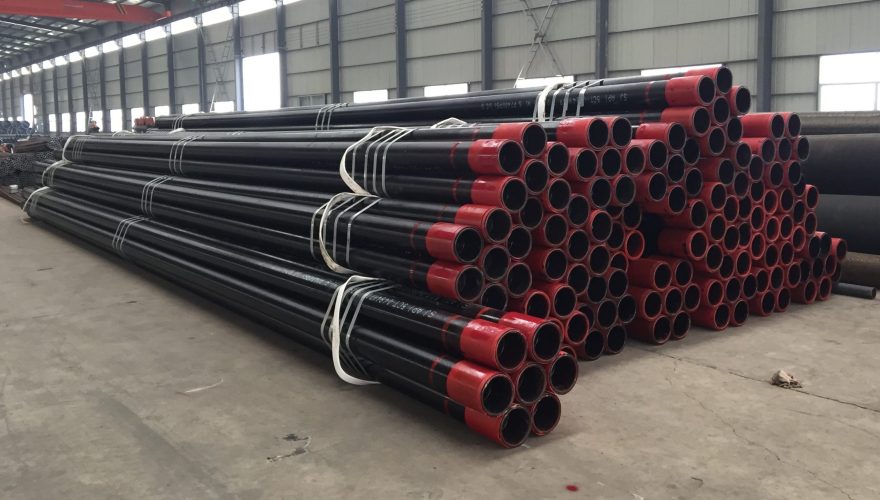

Custom Fire Fighting Pipes,Seamless and Welded Steel Pipes Manufacturer Since 1991.

Application:Drilling and Extraction of Oil and Gas

Project:Oil and Gas Project

Product:Seamless & Welded steel pipe

Specification:1/2″ – 20″

Quantity:2500 tons

Year:2018-2022

Country:Colombia, Peru, Pakistan, Dubai, Saudi Arabia, Indonesia etc

Certificate:API 5CT

OCTG means Oil Country Tubular Goods, which refers to steel used in oil and gas extraction and production processes, including Drill pipe, Casing, Tubing, Couplings, Connections and Accessories, for the oil and gas industry on land and offshore. API 5CT is the most common and important standard to ensure the normal production and exploitation of oil and gas.

OCTG casing, which can also be referred to as “encasement pipe”, is used as a protective layer, which surrounds the steel tubing.

Casing is placed before drilling begins and completely surrounds the wellbore. Its purpose is to protect the soil layers and groundwater from contamination by drilling mud and/or frac fluids. Additionally, casing stabilizes the wellbore. Drilling and casing operations alternate – the drill string is removed at predetermined intervals and the wellbore is lined and cemented with casing.

The casing holds the drill string, preventing the unstable upper formation from caving in and prevention of contamination of water well zones; Provides an even internal bore for easy installation of the production equipment;Helps prevention of the contamination of production zones; Helps prevention of fluid (oil) loss;Helps seal off the high-pressure zones from the surface of the earth.

Standard: API 5CT Grades: J55/K55, N80-1, N80Q, C90, T95, P110, Q125 and 13Cr Casing Range of Sizes: 5 1/2” to 20” Length: R2, R3 Ends Type: BTC (Buttress Thread Coupling), LTC (Long Buttress Thread Coupling), Premium connection

Tubing is used to carry petroleum from the well’s depths to the surface. This is the third phase of the wellbore process. Oil and gas occasionally self-elevate to the surface; however, pumps are typically required to bring the fluids to the surface. Besides the 4 1/2-inch diameter, tubing is normally smaller in diameter than casing. Consequently, tubing must be affixed to external support structures, such as a rig or platform, in order to prevent collapse due to pressure differentials.

maintain borehold stability; prevent contamination of water sands; isolate water from producing formations; control well pressures during all phases of drilling, production, and workover operations.

Standard:API 5CT Grade: J55, K55, N80-1, N80Q, C90, C95, P110, Q125 Tubing range of Sizes: 1.05”, 1.315”, 1.66”, 1.9”, 2 3/8”, 3 1/2” and 4 1/2” Length: R2, R3 Ends Type: BTC, UN, EUE, Premium ends that could completely replace the tubing premium connection of Vam, Tenaris, Hunting, TSH etc.

More than a manufacturer, we provide a one-stop solution for your business.