JIS G3444 ERW Steel Pipes

JIS G3444 indicated welded or consistent carbon steel tubes for general auxiliary purposes, civil designing, engineering, steel towers, frameworks, swaggers, heaps for concealment of avalanche and different structures.

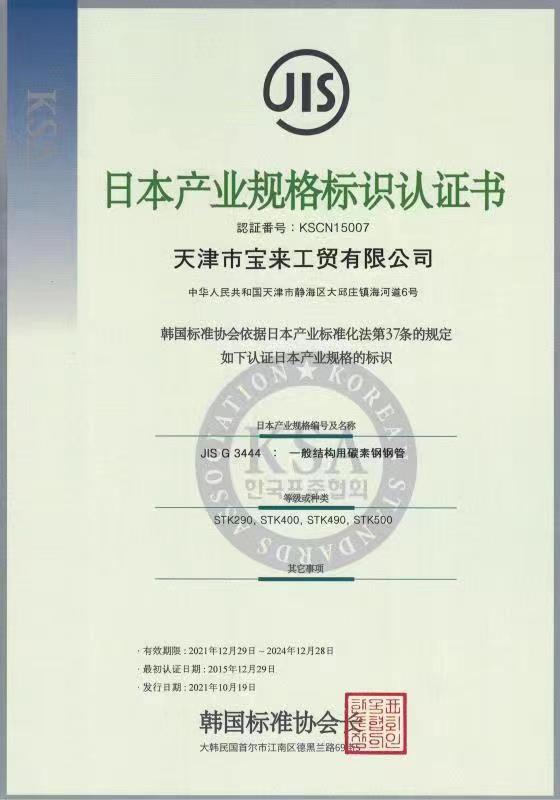

JIS G3444 Certification

JIS G3444 ERW steel pipe is produced in Lai’s factory according strict accordance with the standards. Our mainly market are Japan and Philippines.

Scaffolding is a common use of JIS G3444 steel pipes. The outside diameter is 48.3mm with thickness 3.2 or 4.0mm.

Usually the surface is hot dipped galvanized with zinc coating above 210g/㎡, which offers long term corrosion resistance.

Scaffold tubes, also called scaffolding tubes, is the main component of the scaffolding construction system. Scaffolding tube are widely used as a temporary structure to help workers craw and repair building in height. Also scaffolding tubes are frequently be used in formwork and shoring system.

Example Size

Note: Some of the main specifications are shown below, please contact us for more details.

Outside Diameter | Wall Thickness | Cross Sectional Area | Weight | Moment of Inertia | Moduius of Section | Radius of Gyration |

mm | mm | cm² | kg/m | cm² | cm² | cm |

21.7 | 2.0 | 1.238 | 0.972 | 0.672 | 0.560 | 0.700 |

60.5 | 2.3 | 4.205 | 3.30 | 17.8 | 5.90 | 2.06 |

3.2 | 5.760 | 4.52 | 23.7 | 7.84 | 2.03 | |

4.0 | 7.100 | 5.57 | 28.5 | 9.41 | 2.00 | |

139.8 | 3.6 | 15.40 | 12.1 | 357 | 5.11 | 4.82 |

4.0 | 17.07 | 13.4 | 394 | 56.3 | 4.80 | |

4.5 | 19.13 | 15.0 | 438 | 62.7 | 4.79 | |

6.0 | 25.22 | 19.8 | 566 | 80.9 | 4.47 | |

267.4 | 6.0 | 49.27 | 38.7 | 421X10 | 315 | 9.24 |

6.6 | 54.08 | 42.4 | 460X10 | 344 | 9.22 | |

7.0 | 57.26 | 45.0 | 486X10 | 363 | 9.21 | |

8.0 | 65.19 | 51.2 | 549X10 | 411 | 9.18 | |

9.0 | 73.06 | 57.3 | 611X10 | 457 | 9.14 | |

9.3 | 75.41 | 59.2 | 629X10 | 470 | 9.13 |

One-stop service to facilitate your purchase

The Lai Group continues to provide service and support after your purchase. To save you time, we offer you numerous value-added services such as processing, logistics management and testing.

Processing Services:

- OEM & ODM

- Protective Coatings

- Saw and Flame Cutting

- Beveling, Threading and Grooving