ASTM A53/ API 5L Hot Dipped Galvanized ERW Steel Pipe

Application for Hot Dipped Galvanized Pipe

Pre-Galvanized Steel Pipe Used for Greenhouse Frame

Hot Dipped Galvanized Pipe Used in Highway Guardrail

Advantage of hot dipped galvanized coating

- Uniform Coating

- Strong Adhesion

- Strong Corrosion Resistance

- Long Service Life

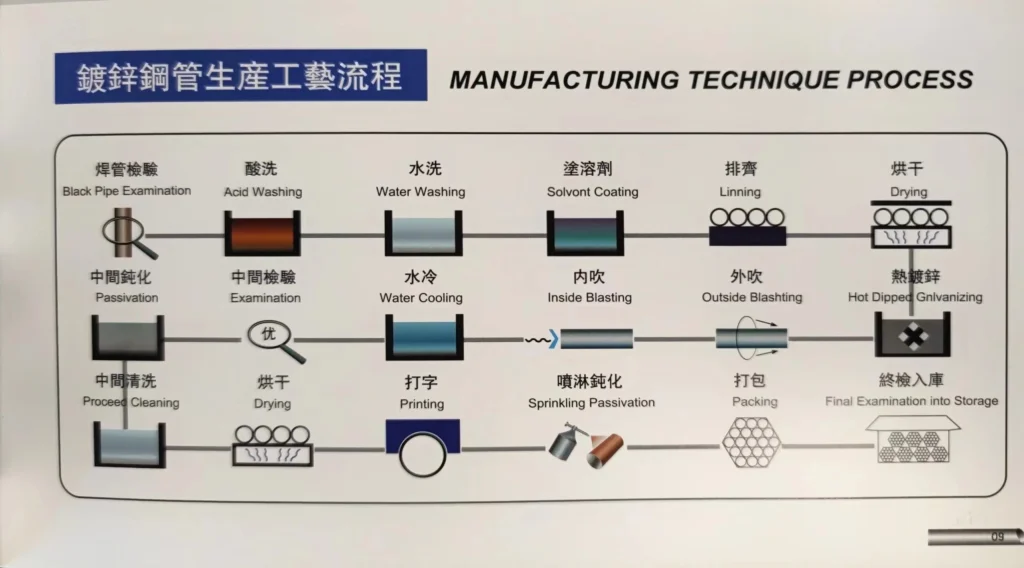

Hot Dipped Galvanized Process

The hot-dip galvanized pipe is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined.

1. Hot-dip galvanizing is to pickle the steel pipe first. It is cleaned in the tank of ammonium chloride or zinc chloride aqueous solution or mixed aqueous solution of ammonium chloride and zinc chloride.

2. Pipe is sent to the hot dip coating tank.

3. The passivation solution is then sent to protect the zinc layer.

4. The final step is cooling.

What's the different between of Pre-Galvanized and Hot Dipped Galvanized?

Hot dipped galvanization is an economical choice for anticorrosion. It is often used on objects that have been fabricated beforehand but yet to be galvanized and the hot-dipped galvanization plays as the last step.

Meanwhile, pre-galvanizing, as its name implies, is performed at the first stage of production. Hence, it mainly occurred at the mills, and the results of the process will be cut into size and fabricated later.

a. Coating thickness

Both methods result in a uniform thickness for the coating. However, the hot-dipped galvanization produces a thicker layer of protection than the pre-galvanization does. The minimum average thickness of hot-dip galvanized steel is of 200 – 550g/㎡ while it is between 40 -100g/㎡ for the pre-galvanized products.

b. Coating bond

The first steps of these hot dipped galvanzied processes of making galvanized steel is cleaning the surface, hence, the bond between the steel and the protective coating is metallurgical and strong.

Example Size

Note: Some of the main specifications are shown below, please contact us for more details.

Designator | DN Designator | Outside Diameter | Wall Thickness |

mm | mm | ||

1/2″ | 15 | 21.3 | 2.77 |

3.73 | |||

4.78 | |||

7.47 | |||

6″ | 150 | 168.3 | 4.78 |

5.56 | |||

6.35 | |||

7.11 | |||

7.92 | |||

8.74 | |||

9.52 | |||

10.97 |

One-stop service to facilitate your purchase

Processing Services:

- OEM & ODM

- Saw and Flame Cutting

- Threading and Bending