FBE (Fusion Bonded Epoxy) Coated Steel Pipe

Fusion Bonded Epoxy (FBE) coated carbon steel pipes are widely used in the oil and gas and water/wastewater industries. They help protect the assets of these industries from corrosion. Apart from the fact that the coating is non-toxic, epoxy coated steel gas pipes have a smooth surface that is easy to clean and maintain. Another benefit of using epoxy-coated black iron pipes is that they tend to withstand extreme temperature environments as they are not subjected to high temperatures of 390 degrees Fahrenheit and are also waterproof.

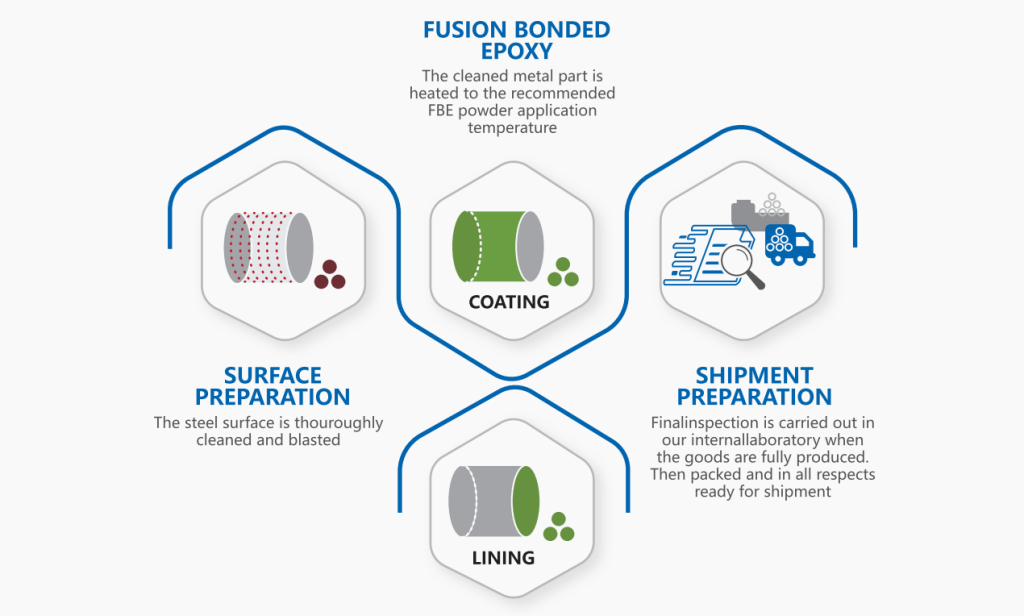

FBE processing flow

Advantages :

1. Long Term Corrosion Protection for Steel Pipes

2. Good Mechanical and Chemical Resistance

3. Extend the actual use time of the pipe

4. Quick changeover times to other diameters

5. Reduce the cost of pipe repair and replacement

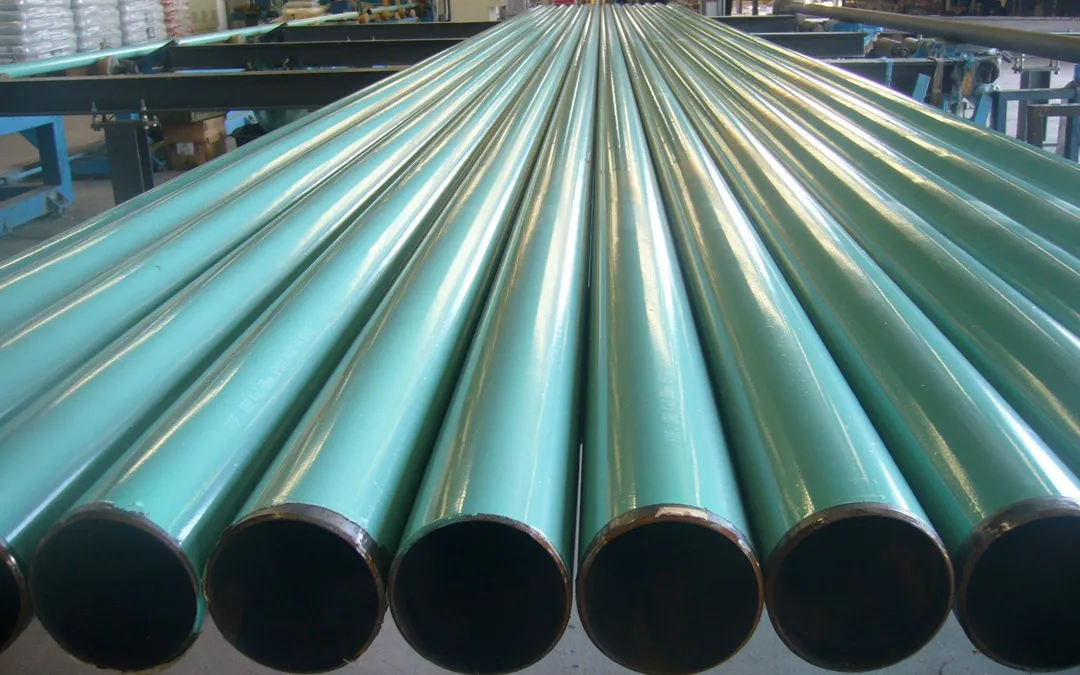

6. Customized color according to different industries

Colour Choose :

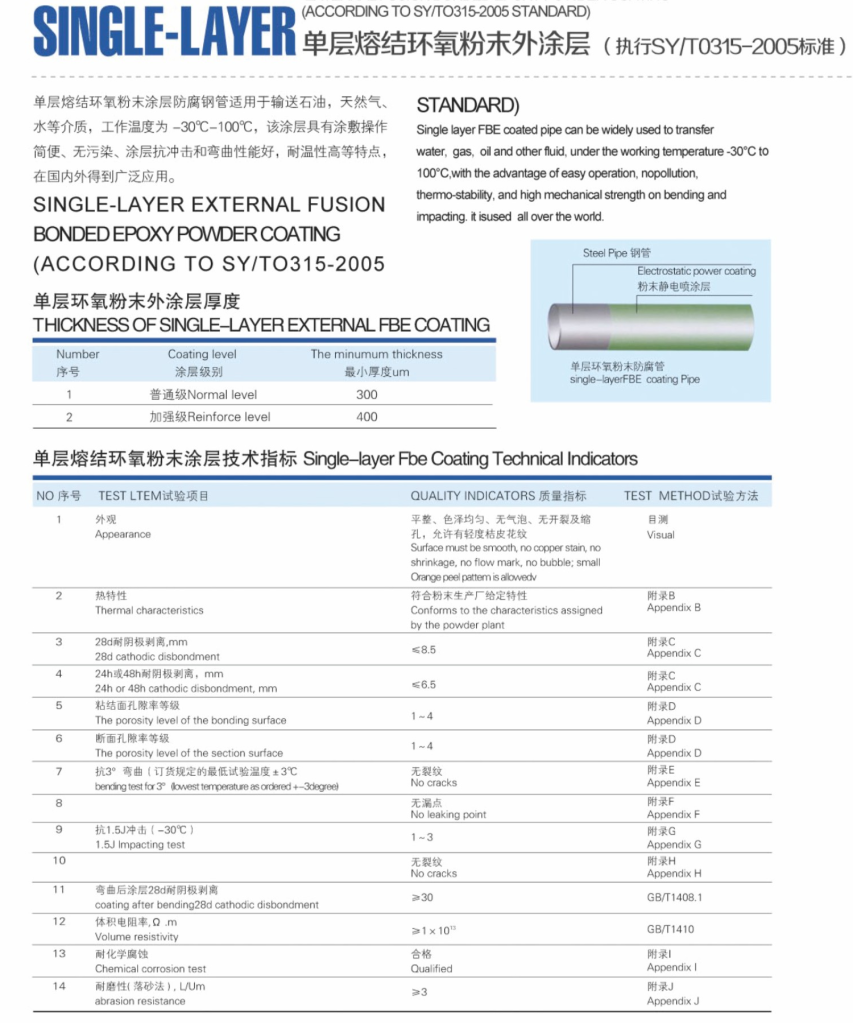

External FBE Processing

Heating after Shot Peening and Descaling

Cooling after electrostatic spraying

Technical and Inspection Parameters