ASTM A53 Fire Protection Pipes

ASTM A53 ERW fire protection pipes are formed by rolling strip and welding the seam, with precise dimension and light weight. It can be used for water, steam and air conveyance.

Fire pipe specifications that we can supply

Pipes are the central component of a fixed fire protection system. Pipes transport and distribute fire extinguishing fluids (water, gas, foam solutions, etc.) from their source to discharge devices installed in protected areas.

The types of piping that can be used are defined by the standards for the installation of fire protection systems.

The different standards for fire protection installations specify the permitted manufacturing processes, dimensions and sizes of carbon steel pipes.

Welded and seamless pipes manufactured according to the following pipe standards are acceptable.

European standards

EN 10255M, EN 10224, EN 10217-1, EN 10217-2, BE 1387

ASME Standards

ASTM A53, ASTM A795, ASTM A135, ASTM A106.

A professional team

Customer focused

Normative

We can supply our products to local or international standards on request. We offer tailor-made solutions and competitive, quality products.

Customized service for fire protection pipes

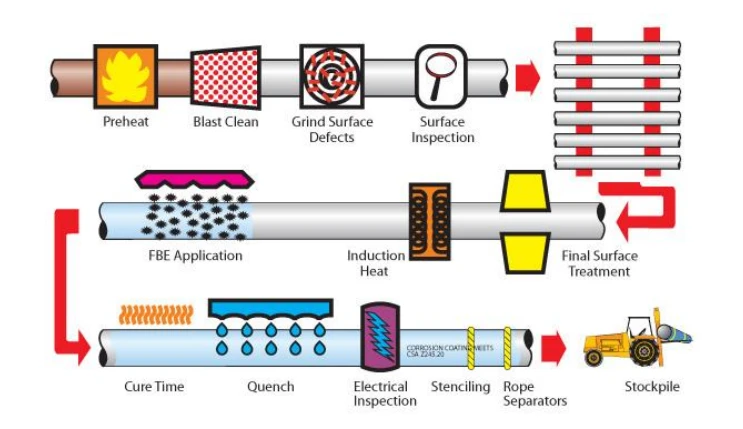

When people purchase steel pipe for pipeline systems, always we see the pipe has been asked for a epoxy coating like FBE.

What is FBE (Fusion Bonded Epoxy) coating steel pipe?

FBE coating pipe is Fusion Bonded Epoxy coating steel pipe. It could be applied for external or internal coating, with heat resin for pipe. With coated a form of dry powder at thickness 400-600 microns on to the heated surface of pipe. Once the FBE coated on the pipe surface, the FBE film provides an extremely hard surface with great adhesion to the pipe surface. The FBE layer in a even form and have good resistance to the chemical reaction.

Advantages :

1. Convenient to sparying, no pollution, excellent resistance for high-temperature(-40°C to 85°C ).

2. High strength and anti-bending performances.

3. Strong adhesion, good integrity, anti soil stress and wear.

Colour Choose :

Example Size

|

|

Outside Diameter(O.D) |

THICKNESS |

Test Pressure |

||

|

DN |

in. |

mm |

mm |

Mpa |

|

|

Sch10 |

25 |

1″ |

33.4 |

2.77 |

4.8 |

|

32 |

1-1/4″ |

42.2 |

2.77 |

9.0 |

|

|

40 |

1-1/2″ |

48.3 |

2.77 |

9.0 |

|

|

50 |

2″ |

60.3 |

2.77 |

13.2 |

|

|

65 |

2-1/2″ |

73 |

3.05 |

12.0 |

|

|

80 |

3″ |

88.9 |

3.05 |

9.9 |

|

|

100 |

4″ |

114.3 |

3.05 |

7.7 |

|

|

125 |

5″ |

141.3 |

3.40 |

6.9 |

|

|

150 |

6″ |

168.3 |

3.40 |

5.8 |

|

|

Sch40 |

25 |

1″ |

33.4 |

3.38 |

4.8 |

|

32 |

1-1/4″ |

42.2 |

3.56 |

9.0 |

|

|

40 |

1-1/2″ |

48.3 |

3.68 |

9.0 |

|

|

50 |

2″ |

60.3 |

3.91 |

17.2 |

|

|

65 |

2-1/2″ |

73 |

5.16 |

17.2 |

|

|

80 |

3″ |

88.9 |

5.49 |

17.2 |

|

|

100 |

4″ |

114.3 |

6.02 |

15.2 |

|

|

125 |

5″ |

141.3 |

6.55 |

13.4 |

|

|

150 |

6″ |

168.3 |

7.11 |

12.3 |

|

One-stop service to facilitate your purchase

Processing Services:

- OEM & ODM

- Protective Coatings

- Saw and Flame Cutting

- Beveling, Threading and Grooving