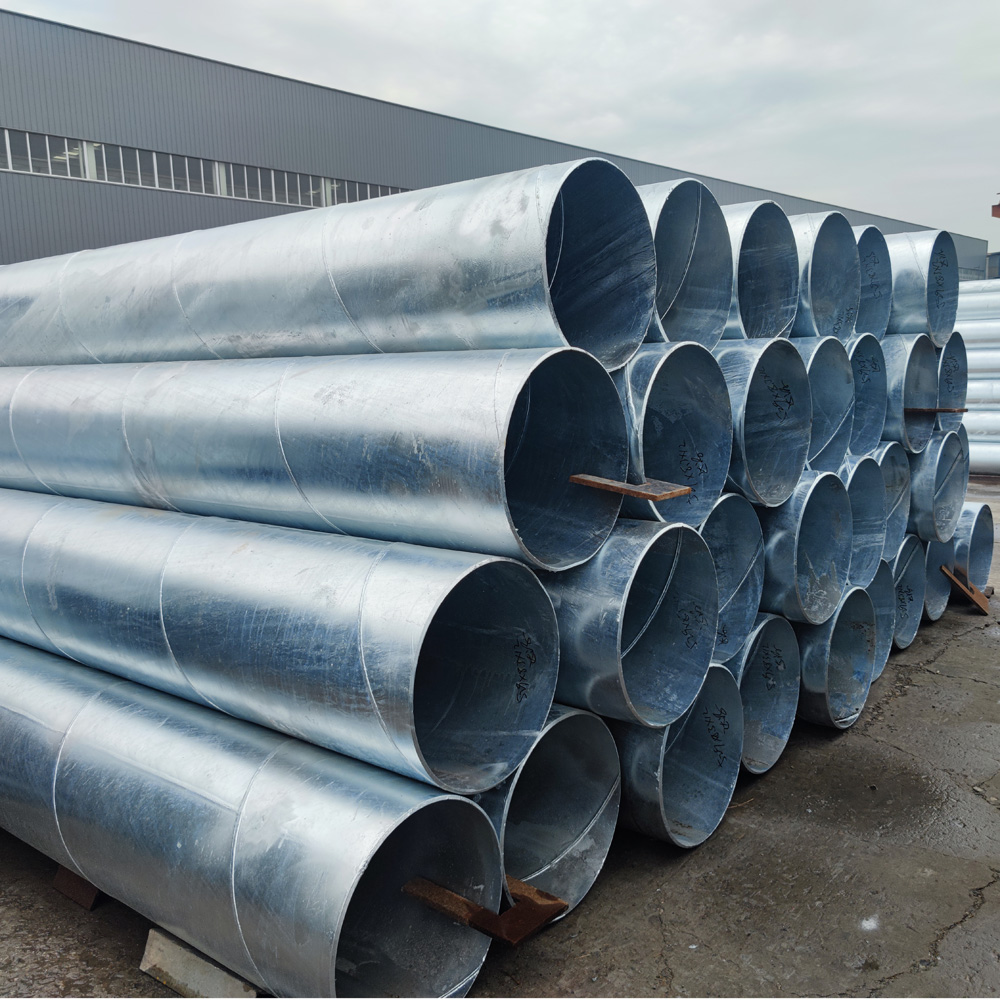

SSAW Steel Pipe manufacturer in China

SSAW steel pipe is formed by rolling and welding a steel strip in a helix or spiral direction, making the weld seam in a spiral line. The spiral welded process makes it possible to create large diameter options. Spiral submerged arc welding pipe is used in pipelines for the transportation and distribution of oil, natural gas, water and other flammable and non-flammable liquids. At the same time, it can be used in structures for construction and other general purposes due to the wide range of sizes.

For the transport of liquids: water supply, drainage. And for transporting gases: gas, steam, liquefied petroleum gas. It is also used for structural purposes: as piling pipe, for bridges, piers, roads, buildings and other pipe structures.

SSAW pipe diameter range is generally 8 inches to 140 inches (219.1mm to 3620mm). The wall thickness is 5.5mm to 24.5mm.

Process of SSAW

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also called HSAW pipe (Helical SAW), welding line shape like a helix. It is using the same welding technology of Submerged Arc-Welding with LSAW pipe. Differently SSAW pipe is spiral welded where the LSAW is longitudinally welded. Manufacturing process is rolling the steel strip, to make the rolling direction have an angle with the direction of the pipe center, forming and welding, so the welding seam is in a spiral line.

Standard of SSAW

We provide all grade of these standards:

API 5L: A, B, X42, X46, X52, X56, X60, X65, X70, X80;

ASTM A53: Gr. A, Gr. B, Gr. C, Gr. D;

ASTM A252: GR 1, GR 2, GR 3

EN10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2;

EN10219: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H

We divide the standard of spiral steel pipe according to different uses:

Classfication | Standard | Mian Products | ||

Line Pipe | API 5L PSL1 | Line Pipe | ||

Casing | API 5CT | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries | ||

Steel Pipe for Fluid Service | ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | ||

EN10217-2 | Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |||

EN10217-5 | Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |||

Steel Pipe for Ordinary Structure | ASTM A252 | Welded and seamless steel pipe piles | ||

EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |||

EN10219-5 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | |||

One-stop service to facilitate your purchase

Processing Services:

- OEM & ODM

- Protective Coatings

- Saw and Flame Cutting

- Beveling, Threading and Grooving